Pumps are indispensable in industries ranging from construction to agriculture, ensuring smooth liquid transfer and reliable operation. Among them, the self-priming pump is a standout choice thanks to its ability to automatically remove air from the suction line and resume pumping without manual intervention. This feature significantly reduces downtime and simplifies operations, especially in remote or intermittent systems.

In this article, SK Tech – a trusted industrial pump supplier in Vietnam – presents a detailed guide to self-priming pumps, covering definitions, working principles, types, applications, advantages, disadvantages, and recommendations on where to purchase high-quality products.

What is a Self-Priming Pump?

A self-priming pump is a centrifugal pump engineered to evacuate air from the suction line and create a vacuum, allowing it to lift liquid into the casing. Unlike standard centrifugal pumps, which require manual priming or a foot valve, a self-priming pump automatically re-primes after initial filling. This makes it ideal for systems that are not continuously flooded or need frequent stops and starts.

Key attributes of self-priming pumps:

- Ability to handle air-liquid mixtures without losing prime.

- Convenient for intermittent or portable applications.

- Eliminates the need for external priming systems.

This design improves operational efficiency and is widely adopted across industries where reliability and reduced maintenance are critical.

Types of Self-Priming Pumps

There are several types of self-priming pumps, each tailored to different fluids and operational environments. Understanding these types helps users choose the most suitable pump for their needs.

Self-Priming Centrifugal Pumps

These are the most widely used self-priming pumps, designed for clean water or low-viscosity liquids. They are common in irrigation systems, domestic water supply, and light industrial processes. Their simple structure allows for low maintenance and long-term durability.

Self-Priming Trash or Sewage Pumps

These pumps are engineered to handle liquids containing solids, debris, or sludge. They are frequently used in construction sites, flood control, and wastewater treatment plants. Their ability to pass solids without clogging makes them invaluable for heavy-duty dewatering tasks.

Self-Priming Diaphragm Pumps

Instead of impellers, these pumps use a flexible diaphragm to move fluids, making them suitable for handling corrosive or abrasive chemicals. They are widely applied in the chemical, food, and marine industries, where resistance to aggressive fluids is essential.

See more: Comparison of self-priming pumps and centrifugal pumps

How Do Self-Priming Pumps Work?

Unlike conventional centrifugal pumps, which lose prime when air enters the suction line, self-priming pumps can purge air and resume normal operation automatically. This makes them invaluable in applications where suction lines may not remain fully flooded.

Step-by-Step Working Process:

- The pump retains a certain amount of liquid in the casing after shutdown.

- Upon startup, the impeller mixes this retained liquid with air in the suction line.

- This mixture creates a vacuum that draws liquid upward into the casing.

- Once the air is expelled, the pump transitions into normal centrifugal operation, delivering continuous flow.

This unique process ensures seamless operation even after interruptions, reducing downtime and manual intervention.

Applications of Self-Priming Pumps

From construction dewatering to chemical transfer, self-priming pumps are integral to operations where reliability and convenience are paramount. Here are key industries where they excel:

- Construction & Dewatering: Removing water from trenches, basements, and flooded excavation sites.

- Agriculture & Irrigation: Pumping water for crops, livestock, and aquaculture.

- Industrial Wastewater Management: Handling liquids with solids or contaminants.

- Marine & Chemical Industries: Safely transferring corrosive or abrasive fluids in harsh environments.

Advantages and Disadvantages of Self-Priming Pumps

Before deciding whether a self-priming pump is the right solution for your application, it is essential to analyze both its strengths and limitations. This understanding will help you make a more informed choice, optimize performance, and avoid unnecessary costs in the long run. Below, SK Tech provides a comprehensive overview of the pros and cons based on real-world industrial use cases.

Advantages of Self-Priming Pumps

Automatic Re-Priming Capability

- Once initially filled, self-priming pumps can automatically evacuate air from the suction line whenever restarted.

- This feature is especially beneficial for operations that require frequent start-stop cycles, such as irrigation systems, dewatering in construction, or emergency pumping scenarios.

Simplified Installation and No Foot Valve Requirement

- Unlike standard centrifugal pumps that require foot valves to prevent air ingress, self-priming pumps operate without additional components.

- This reduces system complexity, installation cost, and potential failure points over time.

Time and Labor Savings

Operators do not need to manually prime the pump before each use, reducing downtime and increasing efficiency in critical operations like flood control or wastewater management.

Versatility Across Applications

- Self-priming pumps can handle a variety of liquids, including water, light slurries, and even solids (in the case of trash pumps).

- They are adaptable for agriculture, marine, industrial, and construction industries.

Ease of Maintenance

With fewer auxiliary components and a straightforward design, these pumps are easier to service, making them cost-effective for long-term use.

Disadvantages of Self-Priming Pumps

Limited Suction Lift

Most self-priming pumps have a suction lift limit of around 7–8 meters. Applications requiring higher lifts may need additional booster systems or alternative pump types like submersible or vacuum-assisted pumps.

Reduced Efficiency During Priming Phase

During the initial priming process, efficiency can drop due to air-liquid mixing. This is normal but may slightly increase energy consumption compared to standard centrifugal pumps.

Need for Initial Filling

Despite their name, self-priming pumps still require an initial fill with liquid. Failure to do so can lead to dry running, which damages seals and impellers.

Higher Initial Cost Compared to Standard Centrifugal Pumps

Due to their specialized design, self-priming pumps generally cost more upfront. However, this cost is offset by reduced maintenance and labor over time.

Not Ideal for All Fluids

While versatile, they may not be suitable for extremely viscous fluids or highly abrasive slurries unless specifically designed for such purposes (e.g., diaphragm self-priming pumps).

See more: Non Self-priming pump different from self-priming pump?

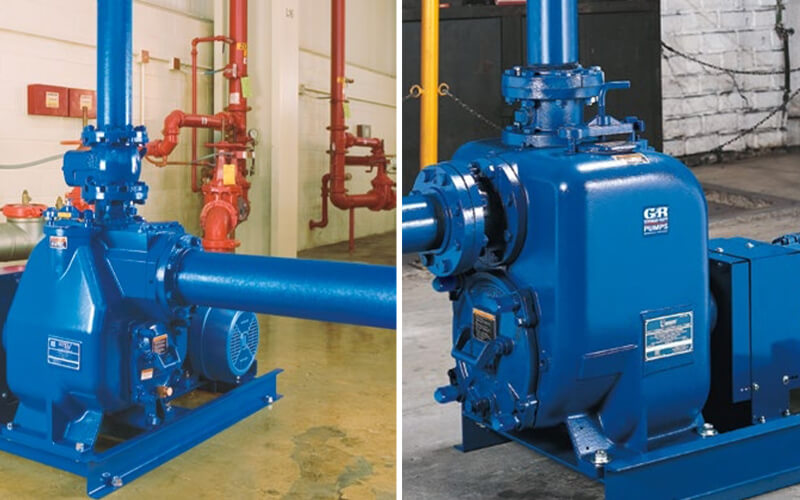

Top Brands of Self-Priming Pumps

When investing in a self-priming pump, brand reputation plays a crucial role in ensuring product quality and support.

SK Tech partners with globally recognized manufacturers to provide pumps that meet rigorous industrial standards. Popular brands include:

- Ebara – Renowned for energy-efficient and durable pumps.

- Tsurumi – Specialists in construction and wastewater solutions.

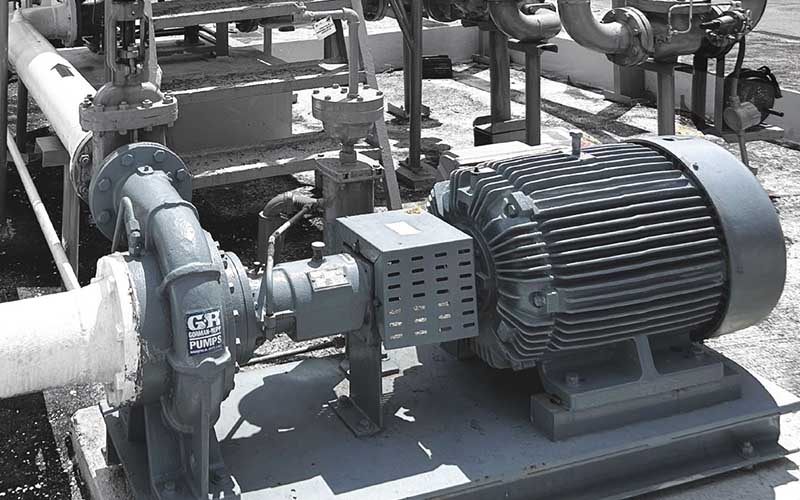

- Gorman-Rupp – Leaders in heavy-duty trash pump technology.

As an authorized distributor, SK Tech provides genuine self-priming pumps with expert consultation and comprehensive maintenance support. Visit www.sktech.com.vn for specifications, recommendations, and competitive quotations tailored to your project.

Conclusion

Self-priming pumps are an efficient and versatile solution for many industries, from agriculture and construction to wastewater and marine applications. Their ability to automatically remove air from the suction line and re-prime themselves greatly simplifies operations, reduces downtime, and lowers maintenance costs.

When choosing the right self-priming pump, it is important to evaluate your specific needs — such as the type of liquid, solids content, suction lift, and operating conditions — to ensure optimal performance.

At SK Tech, we provide genuine self-priming pumps from leading global brands, along with technical consultation and after-sales support. Whether you are looking for a pump for irrigation, construction dewatering, or industrial wastewater, we can help you find the most suitable solution.

Contact us today at SK Tech for expert advice and a tailored quotation.