If your process involves moving oils, fuels, syrups or hydraulic fluids and you need precise, reliable flow, a gear pump is often the best option. In this guide you’ll learn exactly how a gear pump works, why engineers choose internal vs external gear pumps, where they excel (and where they don’t), plus practical advice on selection, maintenance and troubleshooting.

Keep reading – this article will help you select the right pump for your system and avoid common mistakes that cost time and money.

What is a gear pump?

A gear pump is a type of positive displacement rotary pump that moves fluid by trapping it between the teeth of rotating gears and transferring it from the suction side to the discharge side. Because it displaces a fixed volume per revolution, a gear pump delivers a steady, accurate flow that is largely independent of discharge pressure (within design limits).

How does a gear pump work?

Understanding the flow path helps you troubleshoot and choose the right model.

- Intake (suction): As the gears rotate apart at the inlet, they create expanding cavities that draw fluid into the spaces between gear teeth.

- Transfer: The trapped fluid is carried around the casing in the space between gear teeth and the pump housing – mechanical sealing (clearances) prevents backflow.

- Discharge: When gears mesh at the outlet, the fluid is forced out under pressure into the discharge line.

- Recirculation between gear faces is minimized by tight clearances and timing, producing a near-constant volumetric output per revolution.

Note: Because the displacement is per gear revolution, flow rate is proportional to RPM – that makes gear pumps excellent for metering and dosing.

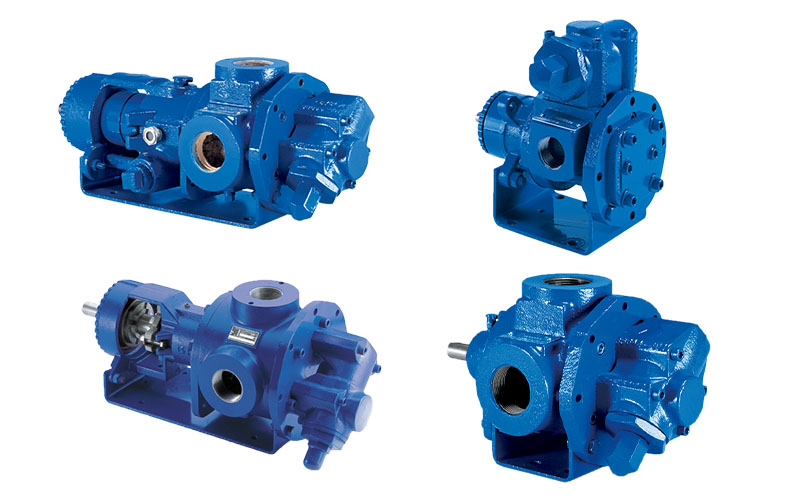

Types of gear pumps

There are several gear pump designs; the two main families are external and internal – each has different strengths.

External gear pumps

- Design: Two external spur gears (driver + idler) rotate in mesh inside a close-fitting casing.

- Strengths: High-pressure capability, simple construction, excellent for hydraulic oil and lubrication systems.

- Common uses: Hydraulic power units, high-pressure oil transfer, industrial lubrication.

Internal (internal-tooth) gear pumps

- Design: A smaller external gear drives a larger internal (annulus) gear; often includes a crescent-shaped partition.

- Strengths: Smoother flow (less pulsation), better for viscous fluids and shear-sensitive products, often quieter.

- Common uses: Food syrups, fuel transfer, dosing viscous oils.

Variants and related rotary pumps

- Helical gear pumps: helical teeth for smoother flow and less noise.

- Gerotor pumps: a rotor-stator internal gear family used where compact size is critical.

- Lobe / vane / screw pumps: not gear pumps but sometimes chosen for larger solids handling or gentler pumping.

Key features & performance characteristics

Knowing performance traits helps you match pump to fluid and duty.

- Flow proportional to RPM: simple speed control gives predictable flow.

- High volumetric efficiency with low slip when clearances are correct.

- Viscosity-capable: gear pumps perform better as viscosity increases (to a point) – they excel with oils, fuel, glycols, heavy hydrocarbons, edible oils, and many chemicals.

- Pressure rating: many gear pumps handle moderate to high pressures (consult manufacturer specs).

- Pulsation: external gears have higher pulsation than internal designs; helical/gerotor types reduce pulsation.

- Shear and heat: gear pumps impart shear and frictional heat – consider for shear-sensitive liquids.

- Self-priming: many gear pumps are effectively self-priming when properly installed (check model).

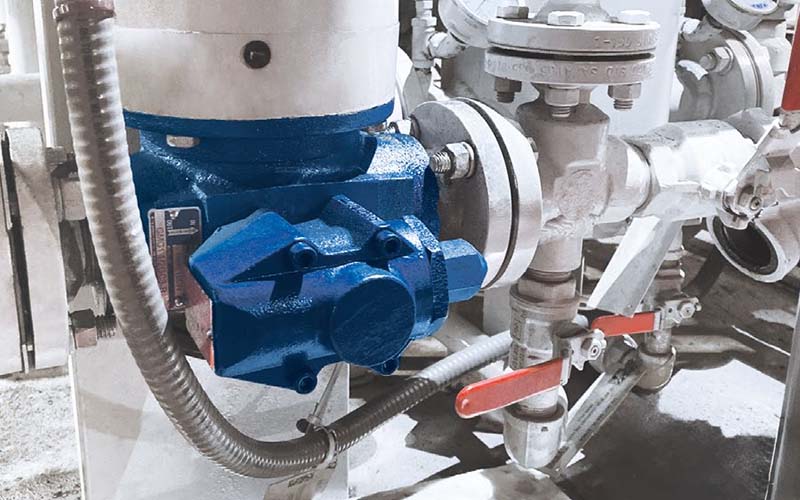

Applications – where gear pumps excel

Here are practical, industry-tested uses where gear pumps are typically the right choice.

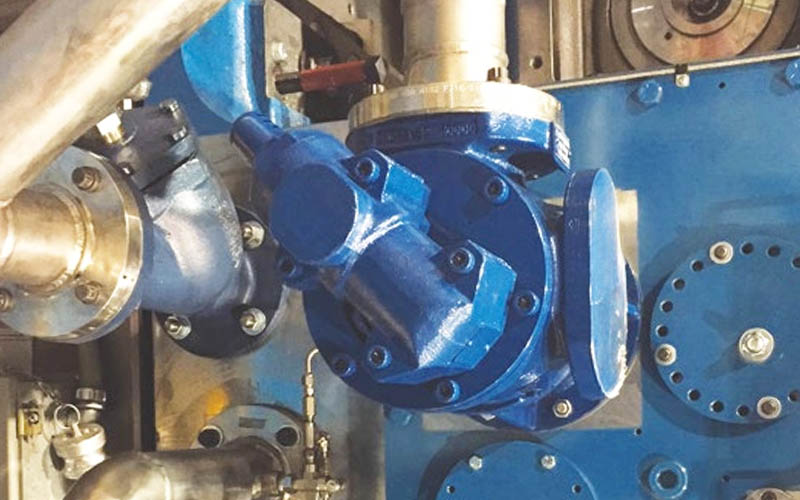

- Hydraulic systems: hydraulic power units and actuators (external gear pumps are common).

- Lubrication systems: steady oil supply to bearings, gearboxes, turbines.

- Fuel and oil transfer: fuel dispensing, bunkering, crude transfer (internal/external depending on specs).

- Chemical dosing & process: metering viscous chemicals at controlled flow rates.

- Food & beverage: chocolate, syrups, edible oils – with food-grade materials and seals.

- Paints, adhesives & resins: controlled transfer of viscous liquids in production lines.

Advantages and limitations (detailed)

Make the decision by weighing the practical pluses and minuses.

Advantages

- Stable, metered flow: excellent for dosing and process control.

- Good with high viscosity: performance improves versus centrifugal pumps for viscous fluids.

- Compact & robust: high power density in a small footprint.

- Low maintenance: simple gear sets are durable and serviceable.

- Repeatable displacement: flow predictability simplifies system design.

Limitations

- Not for abrasive solids: particles will accelerate wear and reduce accuracy.

- Shear & heat generation: may damage shear-sensitive fluids or raise fluid temperature at high speeds.

- Fixed displacement: variable flow needs VFD or mechanical speed control.

- Clearance sensitivity: performance depends on intact clearances – wear reduces efficiency and increases slip.

Gear pump vs other pump types – quick comparison

Use this table to rapidly see when gear pumps are the best fit.

| Criterion | Gear Pump | Centrifugal Pump | Progressive Cavity / Lobe |

| Best for | Viscous fluids, metering | Low-viscosity, high flow | Shear-sensitive, solids |

| Flow control | Proportional to RPM | Depends on system curve | Very steady, low shear |

| Solids handling | Poor | Poor | Good |

| Pressure capability | Good | Moderate | Moderate |

| Pulsation | Moderate (less in internal/gerotor) | Low | Very low |

| Maintenance | Moderate (gear wear) | Moderate | Higher (stator wear) |

How to choose the right gear pump – a practical checklist

Before buying, verify these technical items – they determine long-term success.

- Fluid properties: viscosity, temperature, density, corrosiveness, solids content.

- Required flow & pressure: duty point, maximum pressure, intermittent vs continuous duty.

- Material compatibility: cast iron, ductile iron, stainless steel, bronze – choose per fluid and regulations (food, chemical).

- Seals & bearings: mechanical seal vs packing; plan for seal type vs fluid.

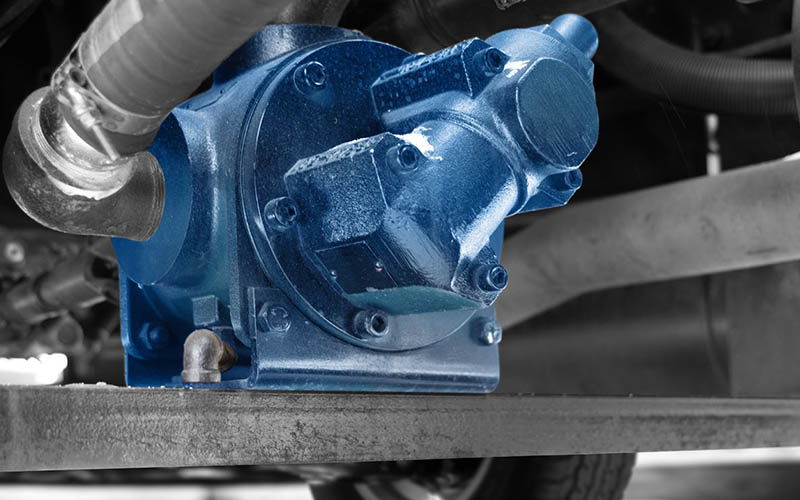

- Mounting & drive: direct-coupled, gearbox, motor speed (RPM range).

- Accuracy and pulsation tolerance: metering needs low pulsation (choose internal or gerotor).

- Regulatory needs: food-grade (FDA), ATEX/IECEx for hazardous areas, API for oil industry.

- Serviceability & spare parts: local support and spare availability (SK Tech can advise).

Installation, maintenance & troubleshooting (practical)

A few simple practices extend life and prevent common failures.

Installation tips

- Ensure proper shaft alignment and rigid mounting.

- Install suction and discharge piping with minimal suction losses – keep suction short and avoid air pockets.

- Use inlet strainer/filters to block debris.

- Verify lubrication requirements (some gear pumps are lubricated by pumped fluid).

Preventive maintenance schedule (example)

- Daily/shift: check for unusual noise, vibration, leakage, temp.

- Weekly: inspect seals and visible fasteners.

- Monthly: measure discharge flow and compare to baseline; check coupling alignment.

- 6–12 months: inspect gear clearances, bearings, replace wear parts as needed.

Common problems & fixes

- Reduced flow → check wear, suction restrictions, air ingestion.

- Noisy operation → check cavitation (suction lift, NPSH), worn bearings.

- Leakage at shaft → inspect mechanical seal or packing.

- Overheating of fluid → reduce speed, check viscosity and fluid compatibility.

Materials, seals & compliance considerations

Selecting materials and seals is critical for compatibility and regulations.

- Cast iron / steel: common for oils, fuels, non-corrosive fluids.

- Stainless steel (304/316): necessary for food, pharma, corrosive chemicals.

- Bronze / nickel alloys: used in marine or specific chemical services.

- Seals: mechanical seals for low leakage, PTFE/ELASTOMER and food-grade options available.

- Certifications: FDA, 3A, ATEX, API – specify per application.

Buying guide – what to ask your supplier

Bring this checklist when requesting quotes to get comparable proposals.

- What is the exact displacement (cc/rev) and expected flow at chosen RPM?

- Maximum allowable pressure and starting torque?

- Recommended clearances and service intervals.

- Materials of wet parts, seal options and spare part lead times.

- Is the pump self-priming for your suction conditions?

- Warranty, after-sales support, local servicing (ASK: SK Tech offers local support).

FAQ - Frequently Asked Questions

Can a gear pump run dry?

Do gear pumps handle abrasive slurries?

Are gear pumps good for metering?

How often should gears be inspected?

Can I use a gear pump for food products?

Conclusion

Gear pumps are a compact, robust and reliable solution when you need consistent flow, accurate metering, and excellent performance with viscous fluids. Choose external gear pumps for high pressure/hydraulic duties and internal or gerotor designs when you need smoother flow and lower pulsation for viscous or food applications. Balance fluid compatibility, operating speed, maintenance access and compliance requirements when selecting a model.

If you need tailored advice or a quotation, SK Tech (www.sktech.com.vn) is an authorized distributor of leading gear pump brands and provides technical selection support, installation guidance and after-sales service. Contact us for a free consultation and to find the right gear pump for your process.