What exactly are industrial pumps? How do they work? What are the different types of industrial pumps, their advantages and limitations, and most importantly, how do you choose the right pump for your specific application? This article by SK Tech, a trusted distributor of genuine industrial pumps, will answer all those questions in detail.

What Are Industrial Pumps?

Industrial pumps are mechanical devices designed to transport fluids (liquids, slurries, and sometimes gases) from one location to another in an industrial setting. Unlike residential or commercial pumps, which are built for relatively light-duty applications such as domestic water supply, industrial pumps are engineered to withstand:

- Continuous operation (24/7 duty cycles)

- High pressures and large flow rates

- Corrosive, abrasive, or viscous fluids

- Harsh environments (chemical plants, mines, offshore platforms, etc.)

At their core, pumps function by converting mechanical energy (from an electric motor, diesel engine, or turbine) into hydraulic energy to move the fluid. But the way this conversion happens depends on the pump type – which brings us to the working principles.

Working Principles of Industrial Pumps

Understanding the working principle of industrial pumps is crucial for selecting the right model. Broadly, all pumps fall into two categories:

Dynamic Pumps (Centrifugal Principle)

Dynamic pumps, especially centrifugal pumps, are the most widely used in industry. They operate by imparting velocity to the fluid via a rotating impeller, then converting that velocity into pressure at the pump outlet.

Step-by-step operation of a centrifugal pump:

- Fluid enters through the suction nozzle into the center (eye) of the impeller.

- The impeller rotates at high speed, transferring kinetic energy to the liquid.

- The fluid moves radially outward into the volute casing or diffuser.

- Kinetic energy is converted into pressure energy, and the liquid exits the pump at the discharge port.

Advantages: High flow rate, simple construction, relatively low cost, minimal maintenance.

Limitations: Efficiency drops with high-viscosity fluids; not self-priming unless specially designed.

Positive Displacement Pumps (Displacement Principle)

Positive displacement (PD) pumps work differently. Instead of imparting velocity, they trap a fixed volume of fluid and physically move it from the inlet to the outlet with each cycle or rotation.

Types of positive displacement pumps include:

- Gear pumps (external & internal) – great for oils, fuels, adhesives.

- Screw pumps – smooth flow, good for viscous fluids.

- Diaphragm pumps – excellent for corrosive chemicals, slurries, acids.

- Piston & plunger pumps – extremely high pressure, precise metering.

Advantages: Constant flow regardless of pressure, excellent with viscous or shear-sensitive liquids, capable of self-priming.

Limitations: More complex, higher maintenance, not ideal for very high flow rates.

Key Difference Between Dynamic and PD Pumps

| Feature | Centrifugal Pumps (Dynamic) | Positive Displacement Pumps |

|---|---|---|

| Flow Behavior | Varies with pressure (system curve dependent) | Constant flow, independent of pressure |

| Best For | Large flow, low to medium viscosity | Viscous fluids, precise dosing |

| Efficiency | Drops with viscosity | Improves with viscosity |

| Maintenance | Lower (fewer moving parts) | Higher (seals, valves, pistons wear) |

| Self-Priming | Rare (special designs only) | Common |

Both principles are essential. In fact, most industries use a mix of centrifugal pumps for water and thin liquids, and positive displacement pumps for oils, chemicals, and metering applications.

Types of Industrial Pumps

Before purchasing or selecting a pump, it’s essential to understand the major types of industrial pumps. Each design has specific strengths, weaknesses, and best-use scenarios. Choosing the wrong pump type often leads to inefficiency, frequent breakdowns, and higher operating costs. Below, we’ll review the most common industrial pump types used across industries.

Centrifugal Pumps

Centrifugal pumps are the most widely used industrial pumps worldwide, thanks to their simplicity and versatility.

Working principle: They use a rotating impeller to accelerate liquid, converting kinetic energy into hydraulic energy (pressure) at the discharge.

Advantages:

- High flow capacity (hundreds to thousands of m³/h)

- Simple design and relatively low cost

- Suitable for continuous duty operations

- Easy to install and maintain

Limitations:

- Poor performance with viscous fluids (efficiency drops)

- Not self-priming unless modified

- Sensitive to changes in suction conditions (cavitation risk)

Applications:

- Water supply and distribution

- Cooling water in power plants

- Wastewater treatment facilities

- Irrigation and agriculture

- Firefighting systems

Gear Pumps (Positive Displacement)

Gear pumps are one of the most common positive displacement pumps, ideal for handling viscous fluids.

Working principle: Fluid is trapped between gear teeth and the pump casing, then carried from inlet to outlet as gears rotate.

Advantages:

- Steady, pulsation-free flow

- Excellent for oils, fuels, and viscous chemicals

- Compact design with high reliability

Limitations:

- Not suitable for abrasive fluids (causes wear)

- Fixed displacement requires speed control for flow adjustment

Applications:

- Lubrication systems in machinery

- Oil transfer (fuel oil, hydraulic oil)

- Food industry: syrups, chocolate, edible oils

- Chemical dosing (with stainless steel construction)

Screw Pumps

Screw pumps use intermeshing screws to move fluid along the pump’s axis.

Advantages:

- Smooth, low-pulsation flow

- Good for very viscous fluids

- Can handle moderate solids in suspension

- Quiet operation

Limitations:

- Larger footprint compared to gear pumps

- Higher cost

- Efficiency drops with very thin liquids

Applications:

- Marine industry (fuel and lube oil transfer)

- Heavy oils, bitumen, molasses

- Offshore and refinery processes

Diaphragm Pumps

Also called air-operated diaphragm pumps (AODD), these pumps use a flexible diaphragm that moves back and forth to displace liquid.

Advantages:

- Excellent chemical resistance (handles acids, solvents, slurries)

- Can run dry without damage

- Self-priming and capable of handling abrasive fluids

Limitations:

- Lower flow rates compared to centrifugal pumps

- Requires compressed air or mechanical actuation

- Diaphragm wear requires replacement

Applications:

- Chemical processing plants

- Paints, adhesives, inks

- Wastewater sludge handling

- Hazardous chemical transfer

Piston and Plunger Pumps

These are high-pressure positive displacement pumps, moving fluid by reciprocating pistons or plungers.

Advantages:

- Extremely high pressure capability (up to thousands of bar)

- Very precise flow control

- Suitable for metering and dosing applications

Limitations:

- Complex design, higher maintenance

- Pulsating flow requires dampeners

- Larger footprint

Applications:

- High-pressure cleaning and jetting

- Hydraulic systems

- Oilfield services (injection, fracking)

- Water desalination (reverse osmosis feed)

Submersible Pumps

These pumps are designed to operate fully submerged in the fluid they are pumping.

Advantages:

- Saves space, no need for priming

- Eliminates suction lift problems

- Suitable for deep wells and flooded areas

Limitations:

- Difficult to maintain (requires pulling the pump out)

- Electrical insulation must be reliable

- Limited material options

Applications:

- Dewatering in construction and mining

- Wastewater treatment (sewage pumps)

- Deep well pumping

Magnetic Drive Pumps

Mag-drive pumps eliminate the mechanical shaft seal by using magnetic coupling between the motor and impeller.

Advantages:

- Zero leakage design – excellent for hazardous chemicals

- Low maintenance (no seal to replace)

- Corrosion-resistant materials available

Limitations:

- Limited to medium pressures and temperatures

- Cannot handle large solids or slurries

- Higher upfront cost

Applications:

- Chemical transfer (acids, solvents)

- Pharmaceutical and food-grade liquids

- Laboratories and clean industries

Slurry Pumps

Designed specifically to handle abrasive mixtures of liquid and solid particles.

Advantages:

- Heavy-duty construction with wear-resistant liners

- Capable of handling high-density slurries

- Long service life in mining operations

Limitations:

- Higher power consumption

- Large size and heavy weight

- Requires more frequent maintenance in severe duty

Applications:

- Mining (ore, tailings)

- Dredging and sand pumping

- Cement and mineral processing

Key Features & Performance Characteristics of Industrial Pumps

Choosing the right industrial pump depends on understanding the performance characteristics that make each design unique. Here are the most important features to evaluate before making a decision:

Flow Rate and Pressure Capability

- Centrifugal pumps are ideal for high flow rates (hundreds or thousands of cubic meters per hour) but moderate pressures.

- Positive displacement pumps maintain constant flow regardless of system pressure, making them better for dosing and high-pressure applications.

Fluid Compatibility

Industrial pumps are exposed to a wide variety of fluids: water, oils, solvents, acids, corrosives, slurries. The chosen material (cast iron, stainless steel, bronze, specialty alloys, or lined plastics) must withstand chemical attack, temperature, and abrasives.

Viscosity Handling

- Centrifugal pumps lose efficiency with viscous fluids.

- Gear and screw pumps perform better as viscosity increases, making them the first choice for oils, adhesives, and resins.

Energy Efficiency

Since pumps can consume up to 20–30% of industrial energy costs, choosing energy-efficient models and operating them near their Best Efficiency Point (BEP) significantly reduces operating expenses.

Durability and Reliability

Industrial pumps must operate in harsh environments — high pressures, abrasive slurries, extreme temperatures. High-quality construction and proper maintenance ensure reliability in continuous 24/7 service.

Special Features

- Self-priming capability for applications where suction lift is required.

- Seal-less magnetic drive pumps for hazardous or toxic fluids.

- Explosion-proof (ATEX) designs for flammable liquids.

- Sanitary pumps meeting FDA/3A standards for food and pharmaceuticals.

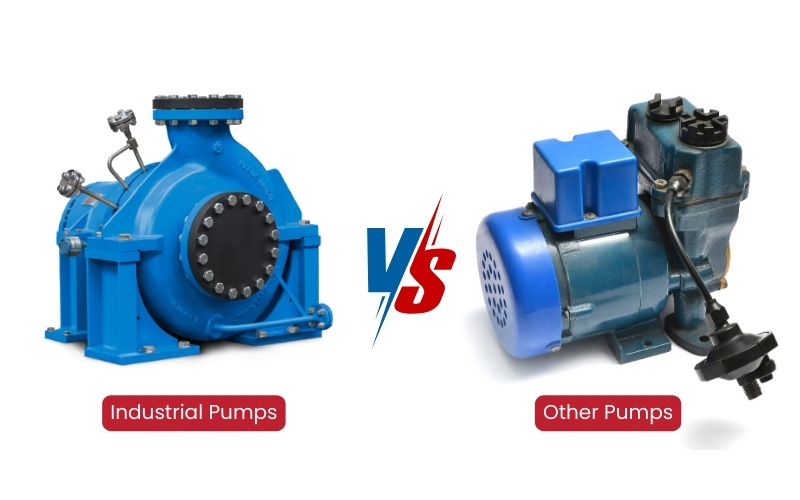

Industrial Pumps vs Other Pump Systems

It’s important to understand how industrial pumps differ from domestic pumps or commercial pumps. While all pumps move fluids, their design intent, performance, and durability vary significantly.

Key Differences

| Feature | Industrial Pumps | Domestic/Commercial Pumps |

|---|---|---|

| Flow & Pressure | High capacity, continuous duty | Low–medium, intermittent use |

| Fluid Handling | Can handle viscous, corrosive, abrasive | Mainly clean water |

| Durability | Designed for 24/7 heavy operation | Shorter lifespan, lighter duty |

| Materials | Stainless steel, alloys, specialized linings | Plastics, cast iron, brass |

| Customization | Widely customizable to application | Limited designs |

| Compliance | API, ATEX, FDA, ISO standards | Few or none |

| Cost | Higher upfront, long-term savings | Lower upfront, more frequent replacement |

Why Choose Industrial Pumps?

- Reliability: Essential in industries where downtime costs millions per hour (e.g., petrochemicals, power generation).

- Efficiency: Properly selected industrial pumps reduce energy waste.

- Safety: Seal-less or explosion-proof pumps ensure compliance in hazardous areas.

- Longevity: A well-maintained industrial pump often outlasts multiple domestic pumps, justifying the investment.

How to Choose the Right Industrial Pump

Selecting the correct industrial pump is one of the most critical engineering and purchasing decisions. An oversized pump wastes energy, while an undersized pump fails to deliver the required performance. Below is a detailed checklist and selection guide to help you make the right choice.

Fluid Properties

- Viscosity: High-viscosity fluids (oils, syrups, adhesives) require positive displacement pumps like gear or screw pumps.

- Corrosiveness: Acids, caustics, and solvents require corrosion-resistant materials (stainless steel 316, Hastelloy, PTFE lining).

- Solids Content: Slurries demand slurry pumps or progressive cavity pumps with abrasion-resistant liners.

- Temperature: For hot fluids (>120°C), check seal and bearing ratings.

Flow Rate and Pressure Requirements

- Flow Rate (Q): Measured in m³/h or GPM – ensure the pump can meet peak demand.

- Head/Pressure (H): Total dynamic head (TDH) must include static lift, friction losses, and system pressure.

- Duty Cycle: Continuous (24/7) or intermittent operation impacts pump sizing.

Materials of Construction

- Cast Iron: Economical, good for water and non-corrosive fluids.

- Stainless Steel: Essential for food, beverage, and corrosive chemicals.

- Bronze/Nickel Alloys: Marine and seawater duty.

- Engineered Plastics: Excellent for acids and chemicals.

Sealing and Bearings

- Mechanical Seals: Best for leak-tight performance; select elastomer compatible with fluid.

- Packed Glands: Lower cost but higher leakage.

- Seal-less Magnetic Drive: Zero-leak option for hazardous or toxic fluids.

Regulatory Standards

Depending on industry, pumps may need to comply with:

- API 610: Petroleum refining.

- ATEX/IECEx: Explosion-proof environments.

- FDA / 3A / EHEDG: Food & pharmaceutical applications.

- ISO/ANSI: General industry standards.

Supplier & Service Support

Even the best pump requires support. Choosing a trusted industrial pump supplier like SK Tech ensures:

- Access to genuine spare parts

- Local technical support

- Training and maintenance services

- Long-term partnerships for reliability

Quick Pump Selection Table

| Application | Recommended Pump Type | Key Notes |

|---|---|---|

| Clean water supply | Centrifugal pump | Low viscosity, high flow |

| Viscous oils | Gear pump, screw pump | Handles high viscosity |

| Slurries (mining, cement) | Slurry pump, progressive cavity pump | Abrasion-resistant design |

| Chemical transfer | Magnetic drive, diaphragm pump | Corrosion resistance |

| Food & beverage | Sanitary gear or centrifugal pump | Stainless steel, FDA compliant |

| High-pressure dosing | Piston or plunger pump | Precise, high pressure |

Leading Industrial Pump Manufacturers & Suppliers

The market for industrial pumps is vast, with dozens of global and regional players. Choosing a reputable manufacturer ensures quality, reliability, and access to spare parts.

Famous Pump Brands Around the World

- Gorman-Rupp (USA): Renowned for self-priming centrifugal pumps, ideal for sewage and flood control.

- Klaus Union (Germany): Expert in sealless magnetic drive pumps for chemical and pharmaceutical industries.

- GEKO Pumpen (Germany): Specializes in high-pressure and portable pumps for construction and emergency use.

- Cat Pumps (USA): Leader in triplex plunger pumps for high-pressure cleaning and industrial applications.

- Grundfos (Denmark): Global leader in water and wastewater pumps, energy-efficient solutions.

- Flowserve (USA): Specializes in engineered pumps for oil, gas, and power sectors.

- KSB (Germany): Wide portfolio covering water, wastewater, and industrial processes.

- Sulzer (Switzerland): Known for chemical process pumps, slurry handling, and custom solutions.

- Ebara (Japan): Trusted for centrifugal and submersible pumps worldwide.

- ITT Goulds Pumps (USA): API-compliant pumps for petrochemicals and refineries.

Why Choose SK Tech as Your Supplier?

At SK Tech, we are proud to be an authorized distributor of genuine industrial pumps from world-class brands. Our value goes beyond just selling pumps:

- Consultation: Our engineers help you select the right pump based on fluid type, flow, pressure, and system design.

- Availability: We supply pumps, spare parts, and accessories quickly to reduce downtime.

- Compliance: We provide pumps certified to API, ATEX, FDA, ISO standards depending on your industry.

- After-Sales Support: Installation assistance, training, and preventive maintenance services.

By choosing SK Tech, you get not only the pump itself but also a long-term partner to support your operations.

FAQ About Industrial Pumps

Here are some frequently asked questions from customers considering industrial pumps:

What is the difference between centrifugal and positive displacement pumps?

Can industrial pumps handle abrasive fluids?

How long does an industrial pump last?

Can industrial pumps run dry?

Conclusion

Industrial pumps are the beating heart of modern industries — without them, water wouldn’t reach our taps, oil wouldn’t flow through pipelines, chemicals couldn’t be processed, and food production would come to a halt. From centrifugal pumps moving millions of liters of water daily to positive displacement pumps dosing precise volumes of chemicals, the right pump is critical for efficiency, safety, and reliability.

When choosing an industrial pump, remember to evaluate:

- The fluid properties (viscosity, abrasiveness, corrosiveness)

- The required flow rate and pressure

- The materials and seals for compatibility

- The industry standards (API, ATEX, FDA, ISO)

- The supplier’s reliability and after-sales support

At SK Tech, we help you make the right choice. As an authorized distributor of leading industrial pump brands, we combine technical expertise, genuine products, and ongoing support to ensure your systems run efficiently and safely.

Whether you need pumps for water, chemicals, oil, or food processing, contact SK Tech (www.sktech.com) today for expert advice and a customized solution.