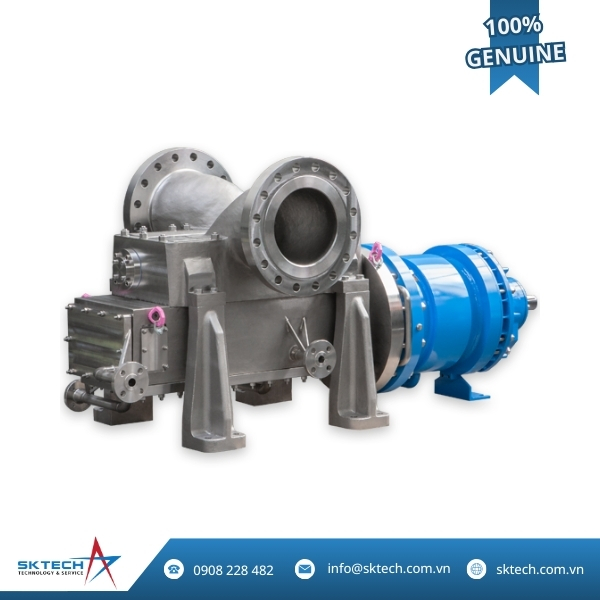

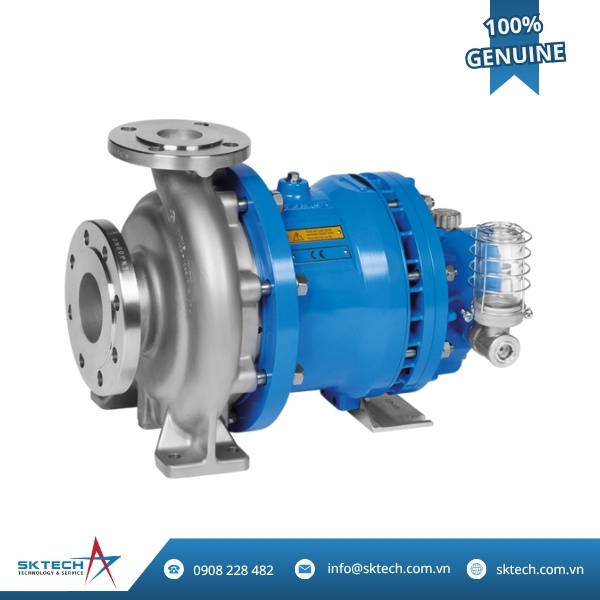

Mag-drive pumps (magnetically coupled pumps) are seal-less pumps that use a magnetic coupling to transfer torque from the motor to the impeller. This design eliminates the need for traditional shaft seals, reducing the risk of leakage and making them ideal for handling hazardous, corrosive, or ultra-pure liquids. Mag-drive pumps are widely used in chemical processing, pharmaceuticals, electronics, and other applications where contamination or fluid loss must be minimized.

Applications

Thanks to their seal-less, leak-proof design, mag-drive pumps are trusted in industries that demand absolute reliability and cleanliness. They are especially suited for transferring aggressive, toxic, or ultra-pure liquids.

- Chemical processing

- Acid and alkaline fluid transfer

- Pharmaceutical manufacturing

- Semiconductor and electronics cooling

- Food and beverage processing

- Water treatment systems

- Laboratory and analytical equipment

- Cleanroom and ultra-pure fluid applications

FAQ – Frequently Asked Questions

What are the advantages of mag-drive pumps over traditional pumps?

Mag-drive pumps are leak-free, maintenance-reduced, and ideal for handling corrosive or toxic fluids. They also prevent contamination and fluid loss, making them safer and cleaner for sensitive environments.

Can mag-drive pumps handle solids or slurries?

Most mag-drive pumps are designed for clean liquids. Solids or abrasive particles can damage the internal components. For slurries, special models or other pump types (like diaphragm or trash pumps) are recommended.

Are mag-drive pumps energy efficient?

Yes. With minimal energy loss from friction (thanks to the seal-less design), mag-drive pumps can be more energy efficient, especially in continuous-duty applications.

What brands of mag-drive pumps are available at SK Tech?

SK Tech proudly distributes premium mag-drive pumps from Klaus Union (Germany) and GEKO Pumpen (Germany), trusted for high chemical resistance and long service life in industrial environments.